When it comes to woodworking and construction projects, choosing the right tool can make all the difference in the quality and efficiency of your work. In this article, we will delve into the world of power saws, specifically exploring the circular saw vs reciprocating saw debate. Understanding the differences and best uses for each tool is crucial for both professionals and DIY enthusiasts alike. By the end of this article, you’ll be equipped with the knowledge to make informed decisions when selecting the right saw for your specific needs. So, let’s dive in and compare these two popular power tools.

Circular Saw Overview

A circular saw is a versatile and powerful cutting tool widely used in woodworking, carpentry, and construction projects. It is designed to quickly and accurately cut through various materials, primarily wood, but also plywood, particleboard, plastic, and even metal when equipped with the appropriate blade.

A common confusion among users is the difference between a skill saw vs circular saw. It’s important to note that a “skill saw” is simply a colloquial term for a circular saw, originating from the brand name Skil, which is well-known for producing circular saws. In essence, a skill saw and a circular saw are the same type of tool, and the terms can be used interchangeably.

The main components of a circular saw include the motor, the blade, the base plate (or shoe), and the blade guard. The motor drives the blade, which is a round, toothed disc, to rotate at high speeds. The base plate provides stability and a flat surface to guide the saw while making cuts. The blade guard covers the blade when not in use and retracts during operation to expose the cutting edge of the blade.

Circular saws are known for their ability to make straight, clean, and precise cuts. They excel at tasks such as ripping (cutting along the grain of the wood) and cross-cutting (cutting across the grain). Some common applications for circular saws include cutting lumber to size, trimming sheet materials like plywood or drywall, and making precise miter and bevel cuts for framing or trim work.

In summary, a circular saw is a powerful and accurate cutting tool best suited for making straight cuts in a wide range of materials. Its versatility and precision make it a go-to choice for both professionals and DIY enthusiasts working on various projects.

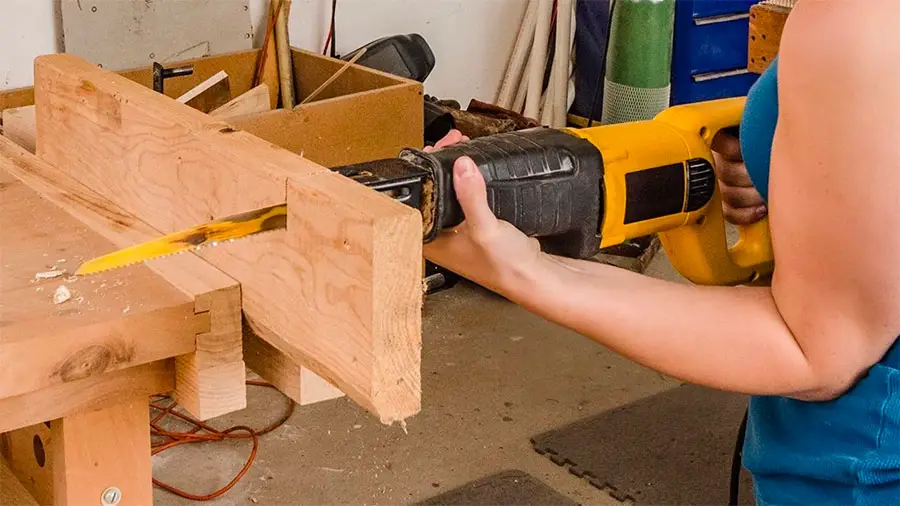

Reciprocating Saw Overview

A reciprocating saw, often referred to as a “Sawzall” (a popular brand name from Milwaukee Tool), is a powerful and versatile cutting tool commonly used in demolition, remodeling, and construction projects. Its primary function is to make rough cuts in various materials, including wood, metal, plastic, and even masonry when paired with the appropriate blade.

The main components of a reciprocating saw include the motor, the blade, the shoe, and the blade clamp. The motor powers the blade’s back-and-forth (reciprocating) motion, enabling it to cut through materials with ease. The shoe provides support and stability during cutting, while the blade clamp allows for quick and easy blade changes.

Reciprocating saws are designed for aggressive cutting and can easily reach tight or awkward spaces where other saws might struggle. They are particularly well-suited for tasks such as cutting through framing, dismantling old structures, pruning tree branches, and making rough cuts in pipes or conduits. While reciprocating saws may not provide the same level of precision as circular saws, their versatility and ability to handle a wide range of materials make them an indispensable tool in many situations.

In summary, a reciprocating saw is a robust and adaptable cutting tool that excels in demolition and remodeling tasks, as well as in situations where access is limited or precision is not the top priority. The Sawzall, a popular brand of reciprocating saws, has become synonymous with this category of tools, further emphasizing their widespread use and importance in various projects.

Comparing Circular Saw vs Reciprocating Saw: Key Differences

Design and Functionality

Circular saws are designed for making precise, straight cuts in various materials, with a rotating, toothed disc-shaped blade. Their motor drives the blade in a circular motion, and the base plate provides stability and guidance during cutting.

Reciprocating saws, on the other hand, use a back-and-forth motion to drive the blade through the material, making them well-suited for more aggressive, rough cuts. Their design allows for easy access to tight or awkward spaces and quick blade changes.

Types of Cuts

Circular saws excel at making straight, clean cuts and are ideal for tasks such as ripping, cross-cutting, miter cuts, and bevel cuts. They are commonly used for cutting lumber, sheet materials, and trim work.

Reciprocating saws are designed for rougher cuts and can tackle a wide range of materials, including wood, metal, plastic, and masonry. They are ideal for demolition, remodeling, and cutting in tight spaces, such as dismantling old structures, pruning tree branches, or cutting pipes and conduits.

Advantages and Disadvantages

Circular Saws

Advantages:

- Precise and straight cuts

- Suitable for a wide range of materials

- Excellent for ripping, cross-cutting, and bevel cuts

Disadvantages:

- Limited to straight cuts

- May struggle in tight or awkward spaces

- Can be less effective in demolition or remodeling tasks

Reciprocating Saws

Advantages:

- Versatile and aggressive cutting ability

- Can access tight or awkward spaces

- Handles a wide range of materials

Disadvantages:

- Less precise compared to circular saws

- Not ideal for fine woodworking or detailed trim work

- May require more control and experience to make clean cuts

In summary, the choice between a circular saw and a reciprocating saw depends on the specific tasks and materials you’ll be working with. Circular saws are best for precise, straight cuts, while reciprocating saws excel at aggressive cutting and working in tight spaces. Each tool has its advantages and disadvantages, so understanding your project requirements will help you make the best decision.

Choosing the Right Tool for the Job

When deciding between a circular saw and a reciprocating saw, it’s essential to consider the specific tasks you’ll be performing, the materials you’ll be cutting, the level of precision required, and any workspace limitations. Here are some guidelines to help you choose the right tool for the job:

- Material being cut: Consider the materials you will be working with most frequently. If you primarily work with wood or sheet materials and need clean, precise cuts, a circular saw is likely the better choice. If you need a saw that can handle a variety of materials, including wood, metal, plastic, and masonry, a reciprocating saw may be more suitable.

- Precision required: Circular saws are known for their accuracy and clean, straight cuts, making them ideal for tasks that require precision, such as woodworking, trim work, or cutting sheet materials. Reciprocating saws, on the other hand, are better suited for rough cuts and demolition work, where precision is less critical.

- Workspace limitations: Consider the space where you’ll be working and any limitations it may impose. Circular saws require more room to maneuver and may struggle in tight or awkward spaces. Reciprocating saws are better suited for working in confined areas, as their design allows for better access to tight spots.

- Type of work: Evaluate the types of projects you typically undertake. If you mostly engage in woodworking, cabinetry, or detailed trim work, a circular saw is likely the better choice. If you frequently work on demolition or remodeling projects that require aggressive cutting or the ability to cut through a wide range of materials, a reciprocating saw may be more appropriate.

- Versatility and frequency of use: If you’re a DIY enthusiast or a professional who needs a versatile saw for a variety of tasks, a reciprocating saw can be a valuable addition to your toolkit. However, if you already own other specialized saws and need a tool primarily for precise, straight cuts, a circular saw might be the better investment.

By considering these factors and understanding the specific requirements of your projects, you can make an informed decision about whether a circular saw or a reciprocating saw is the right tool for your needs.

Safety Considerations

Using power tools like circular saws and reciprocating saws can be dangerous if not handled properly. It’s essential to follow safety precautions to minimize the risk of accidents and injuries. Here are some general safety tips and precautions for using both types of saws:

- Wear appropriate personal protective equipment (PPE): Always wear safety glasses or goggles to protect your eyes from flying debris. Use hearing protection, such as earplugs or earmuffs, to minimize noise exposure. Wear a dust mask or respirator if working in a dusty environment or cutting materials that produce harmful particles.

- Inspect the tool before use: Before using any power tool, check for any damage, loose parts, or other issues that could pose a safety risk. Ensure that the blade is sharp, properly installed, and appropriate for the material being cut.

- Keep your workspace clean and well-lit: A clean, clutter-free workspace minimizes the risk of tripping or accidentally bumping into obstacles. Good lighting is essential for accurate cutting and overall safety.

- Maintain a firm grip and proper footing: Hold the saw with both hands, using a firm grip to maintain control. Ensure that your footing is stable and that you’re not overreaching or standing in an awkward position.

- Use the correct blade: Always use the appropriate blade for the material being cut. Using the wrong blade can result in poor cuts, excessive wear, and even accidents.

- Unplug or remove the battery when changing blades or making adjustments: To prevent accidental starts, always unplug corded saws or remove the battery from cordless saws when changing blades or making any adjustments to the tool.

- Keep the saw’s guards in good working order: Ensure that the blade guard on a circular saw is functioning correctly and not damaged. The guard should cover the blade when not in use and retract smoothly during operation. Similarly, check the shoe and blade clamp on a reciprocating saw to ensure they are secure and functioning properly.

- Allow the saw to reach full speed before cutting: When starting a cut, let the saw reach its full speed before making contact with the material. This ensures a smooth and accurate cut and reduces the risk of the blade binding or kicking back.

- Follow the manufacturer’s guidelines: Always read and follow the instructions provided by the tool’s manufacturer, as they may contain specific safety information and precautions for your particular saw model.

By following these safety tips and precautions, you can minimize the risk of accidents and injuries while using circular and reciprocating saws, allowing you to work confidently and efficiently on your projects.

Conclusion

In conclusion, both circular saws and reciprocating saws are powerful and versatile cutting tools, each with their own unique strengths and applications. Circular saws excel at making precise, straight cuts and are ideal for woodworking, trim work, and cutting sheet materials. Reciprocating saws, on the other hand, are designed for aggressive cutting and are well-suited for demolition, remodeling, and cutting in tight spaces.

When choosing the right tool for your needs, consider factors such as the materials you’ll be working with, the level of precision required, workspace limitations, and the types of projects you typically undertake. Remember that safety is of utmost importance when using any power tool, so always follow the proper precautions and guidelines to minimize the risk of accidents and injuries.

By carefully evaluating your needs and understanding the differences between circular and reciprocating saws, you can make an informed decision and select the best tool for your specific projects. This will enable you to work more efficiently, achieve better results, and ultimately, enjoy greater success in your woodworking and construction endeavors.

FAQ

After our detailed comparison of circular saws and reciprocating saws, you may still have some questions that need clarification. To help further guide your decision-making process, we’ve compiled a list of frequently asked questions that address common concerns and provide additional insights not covered in the main article.

Can I use a circular saw for demolition tasks?

While a circular saw can be used for some demolition tasks, a reciprocating saw is generally more suitable for such projects due to its aggressive cutting ability and versatility.

How do I choose the right blade for my circular or reciprocating saw?

Choose the right blade based on the material you’ll be cutting and the type of cut required. Consider factors like tooth count, blade material, and tooth configuration.

Can a reciprocating saw be used for woodworking projects that require more precision?

A reciprocating saw can be used for woodworking projects requiring more precision, but it may be challenging compared to using a circular saw or other specialized tools designed for precise cuts.

Are cordless circular and reciprocating saws as powerful as their corded counterparts?

Modern cordless circular and reciprocating saws can be nearly as powerful as their corded counterparts, but their performance may depend on factors like battery capacity and motor design.

What maintenance tips should I follow to keep my circular or reciprocating saw in good working condition?

To maintain your circular or reciprocating saw, keep the tool clean, regularly inspect and replace worn or damaged parts, lubricate moving components as needed, and use sharp, appropriate blades.

Can I use a reciprocating saw for plunge cuts or cutting openings in walls?

Yes, a reciprocating saw can be used for plunge cuts and cutting openings in walls, thanks to its ability to make aggressive cuts in various materials and tight spaces.

How do I improve the accuracy of my cuts when using a reciprocating saw?

To improve the accuracy of your cuts with a reciprocating saw, use a sharp, suitable blade, maintain firm control of the saw, use guides or templates when possible, and practice to gain experience.

Leave a Reply