When it comes to woodworking and intricate cutting tasks, the right tool can make all the difference in the world. In particular, the ongoing debate between fret saw vs coping saw has left many hobbyists and professionals alike wondering which saw is best suited for their specific needs. Both saws have their unique advantages and applications, making it essential to understand their differences and when to use each one. In this comprehensive guide, we will delve into the world of fret saws and coping saws, comparing their features, uses, and benefits. By the end of this article, you’ll have a clear understanding of fret saw vs coping saw, enabling you to make an informed decision for your next project.

Fret Saw Overview

Definition and primary features A fret saw is a hand-powered cutting tool designed for intricate and precise cutting tasks, primarily in woodworking. It features a thin, delicate blade held in a deep, U-shaped frame, which allows for increased maneuverability and access to tight spaces. The blade can be easily removed and replaced, enabling users to switch between different blade types to suit the material and level of detail required.

Common uses and applications Fret saws are commonly used for various intricate woodworking tasks, such as:

- Cutting delicate, detailed patterns in wood, plastic, or other thin materials

- Creating scrollwork, marquetry, and inlays

- Cutting tight curves and complex shapes with precision

- Removing interior sections of a workpiece without affecting the outer edges, also known as piercing work

Advantages and disadvantages

Advantages:

- High precision and control for detailed cutting tasks

- Allows for cutting tight curves and intricate shapes

- Deep frame provides access to hard-to-reach areas

- Interchangeable blades to suit different materials and applications

Disadvantages:

- Not well-suited for heavy-duty cutting or thick materials

- Can be challenging for beginners to use effectively due to the delicate nature of the blade

- Blade replacement can be time-consuming and may require additional tools

Coping Saw Overview

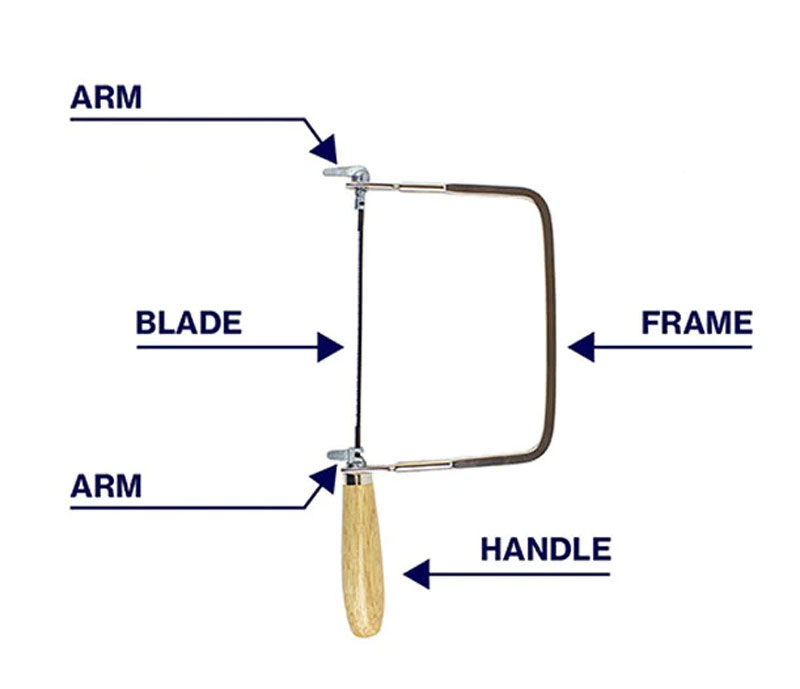

Definition and primary features A coping saw is a versatile hand tool used for cutting curves and intricate shapes in various materials, including wood, plastic, and metal. It consists of a thin, flexible blade held in a shallow, D-shaped frame with a handle at one end. The blade can be rotated and adjusted to different angles, allowing for greater control and precision when cutting. Like the fret saw, coping saw blades can be easily replaced to suit specific materials and cutting requirements.

Common uses and applications Coping saws are widely used for a range of woodworking and carpentry tasks, such as:

- Cutting curves and intricate shapes in wood, plastic, or metal

- Coping joints for molding and trim work

- Removing waste material from dovetail and other types of joints

- Cutting out interior sections of a workpiece, similar to piercing work with a fret saw

Advantages and disadvantages

Advantages:

- Versatile tool for cutting various materials, including wood, plastic, and metal

- Adjustable blade angle allows for greater control and precision

- Ideal for coping joints in molding and trim work

- Sturdier than a fret saw, making it suitable for slightly thicker materials

Disadvantages:

- Not as precise as a fret saw for highly intricate and detailed work

- Shallow frame limits access to tight spaces and hard-to-reach areas

- Blade replacement can be cumbersome and may require additional tools

Key Differences Between Fret Saws and Coping Saws

Blade types and interchangeability

Both fret saws and coping saws allow for blade interchangeability, enabling users to switch between different blade types to suit various materials and cutting requirements. However, fret saw blades are generally thinner and more delicate compared to coping saw blades, which tend to be wider and more robust. Consequently, fret saws are better suited for extremely intricate and detailed work, while coping saws are more versatile for cutting a range of materials.

Cutting capacity and materials

Fret saws excel at cutting thin materials such as veneers, plywood, and plastics, with their delicate blades providing exceptional precision for detailed patterns and designs. Conversely, coping saws are designed to handle a wider range of materials, including wood, plastic, and metal, with their sturdier blades and adjustable angles offering increased cutting capacity.

Precision and control

Fret saws offer superior precision and control for cutting intricate shapes and tight curves, making them ideal for scrollwork, marquetry, and inlays. Coping saws, while still capable of cutting curves and complex shapes, may not provide the same level of precision as fret saws, especially in highly detailed work. However, coping saws are better suited for tasks such as coping joints and cutting through slightly thicker materials.

Ease of use and versatility

Coping saws are generally considered more versatile and easier to use for a wider range of applications, thanks to their adjustable blade angles and ability to cut various materials. Fret saws, while offering greater precision for intricate work, can be more challenging to master due to their delicate blades and deep frame. For beginners, a coping saw may be more accessible, while experienced woodworkers may prefer the precision of a fret saw for specific tasks.

Choosing the Right Saw for Your Project

Factors to consider when selecting a saw:

- Project requirements: Consider the specific tasks you need to accomplish, such as cutting intricate patterns, creating joints, or shaping curves.

- Material type and thickness: Evaluate the materials you will be working with, including their type and thickness, as this will help determine which saw is best suited for the job.

- Level of detail and intricacy: Assess the level of precision and detail required for your project, as this can influence whether you need a fret saw or a coping saw.

- Budget and tool availability: Keep your budget and the availability of tools in mind when choosing between a fret saw and a coping saw, as some saws may be more expensive or difficult to find.

Specific applications and recommended saw types:

- Intricate woodworking and scroll work: For delicate patterns, scrollwork, marquetry, and inlays, a fret saw is the ideal choice due to its precision and ability to cut tight curves.

- Cutting curves and coping joints: A coping saw is recommended for cutting curves in various materials and creating coping joints in molding and trim work, as it offers versatility and sturdiness.

- Craft and hobby projects: For a wide range of craft and hobby projects involving cutting various materials, a coping saw is a versatile choice, while a fret saw may be preferred for highly detailed work.

- General carpentry and home improvement tasks: For general carpentry and home improvement tasks that require a mix of cutting capabilities, a coping saw offers greater versatility and ease of use, making it the better option in most cases.

Tips for Using Fret Saws and Coping Saws Safely and Effectively

Proper blade selection and installation

Choose the right blade for the material and level of detail required for your project. Fret saws typically use thinner blades for intricate work, while coping saws have wider, sturdier blades for various materials. Ensure the blade is properly installed and securely fastened before starting your work. Check the blade tension and adjust if necessary, as an improperly tensioned blade can lead to uneven cuts or even breakage.

Securing the workpiece

Before cutting, make sure to properly secure the workpiece to prevent movement during the cutting process. Use clamps, vises, or bench hooks to hold the material in place, ensuring that it is stable and secure without damaging the workpiece.

Cutting techniques for optimal results

For both fret saws and coping saws, use smooth, controlled strokes while cutting to achieve clean, precise results. Apply consistent, gentle pressure and allow the saw’s teeth to do the work, avoiding excessive force that could cause the blade to bend or break. When cutting curves, gradually rotate the workpiece while keeping the saw at a consistent angle.

Safety precautions and best practices

- Always wear appropriate safety gear, including eye protection and gloves, to protect yourself from flying debris and sharp edges.

- Inspect your saw and blade before each use to ensure they are in good working condition.

- Keep your work area clean and well-lit to reduce the risk of accidents.

- Maintain a proper body position and avoid reaching across the cutting path to minimize the chance of injury.

- Keep your saw blades clean and sharp, as dull or dirty blades can lead to rough cuts and increase the risk of accidents.

FAQ

Can I use a fret saw or coping saw for cutting metal?

While both fret saws and coping saws can be used for cutting thin metal sheets, it is important to use the appropriate blade designed for cutting metal. For fret saws, choose a blade with finer teeth and higher tooth count, as this will provide a smoother cut and minimize the risk of damaging the material. For coping saws, use a blade specifically designed for metal, featuring hardened teeth and a higher tooth per inch (TPI) count. Keep in mind that these saws are generally suited for cutting thin metals and may not be appropriate for thicker or harder metals.

How often should I replace the blades on my fret saw or coping saw?

The frequency of blade replacement depends on factors such as the materials being cut, the quality of the blade, and how often you use the saw. If you notice a decrease in cutting performance, difficulty controlling the saw, or excessive binding during cuts, it may be time to replace the blade. Additionally, inspect the blade regularly for signs of wear, damage, or dullness, and replace it when necessary to ensure optimal cutting performance and safety.

What are the recommended blade types for different materials when using a fret saw or coping saw?

For fret saws, select a blade with a higher tooth count for cutting hard materials such as hardwood, metal, and plastic, and a lower tooth count for softwoods and other soft materials. For coping saws, use a coarse-toothed blade for cutting soft materials and a fine-toothed blade for harder materials. In both cases, ensure the blade is specifically designed for the material being cut to avoid damage or suboptimal performance.

How do I properly maintain my fret saw or coping saw to ensure longevity and optimal performance?

To maintain your fret saw or coping saw, regularly inspect the frame and handle for damage or wear, and tighten any loose hardware. Keep the blades clean, free of debris, and sharp, replacing them when necessary. When not in use, store your saw in a dry, temperature-controlled environment to prevent rust and corrosion. Lubricate any moving parts, such as the blade tensioning mechanism, as needed to ensure smooth operation.

Are there any alternative tools I should consider for intricate cutting tasks aside from fret saws and coping saws?

Alternative tools for intricate cutting tasks include scroll saws and jigsaws, both of which are power tools that provide precise cutting capabilities. Scroll saws are particularly well-suited for detailed work, offering a level of precision similar to fret saws but with the added advantage of power assistance. Jigsaws are versatile tools that can handle a range of materials and thicknesses, providing a more powerful alternative to coping saws for certain tasks.

How can I improve my cutting accuracy and precision with a fret saw or coping saw?

To improve cutting accuracy and precision with a fret saw or coping saw, practice proper cutting techniques, such as using smooth, controlled strokes and applying consistent pressure. Secure the workpiece firmly to prevent movement during cutting, and use a sharp, appropriate blade for the material being cut. Take your time, especially when working on intricate designs or tight curves, and consider using a stencil or template to guide your cuts.

Can I use a fret saw or coping saw for cutting thicker materials, like hardwood or metal sheets?

Fret saws are generally not well-suited for cutting thicker materials due to their delicate blades, which may bend or break under excessive pressure. Coping saws, on the other hand, can handle slightly thicker materials, including hardwood and thin metal sheets, but may struggle with very thick or hard materials. For thicker materials, consider using alternative tools like a jigsaw or a bandsaw, which are designed to handle a wider range of materials and thicknesses more effectively.

What are some common challenges and troubleshooting tips when using a fret saw or coping saw?

- Difficulty cutting straight lines: To maintain a straight cut, use a guide or fence, mark the cutting line clearly, and practice keeping your eye on the line while maintaining a steady, controlled pace.

- Difficulty cutting curves and intricate patterns: Practice cutting curves slowly, rotating the workpiece as needed to guide the saw through the curve. For intricate patterns, consider using a stencil or template to guide your cuts.

- Blade binding during cuts: Ensure that the blade is properly tensioned, sharp, and suited for the material being cut. Apply consistent pressure and avoid forcing the saw through the material.

- Blade breakage: Use the correct blade for the material and thickness being cut, and ensure that the blade is properly tensioned. Avoid applying excessive pressure or bending the blade during cutting.

- Inaccurate cuts: Double-check your measurements and markings before cutting, use guides or templates when necessary, and practice good cutting technique to ensure clean, precise cuts.

- Workpiece movement during cutting: Secure the workpiece using clamps, vises, or bench hooks to prevent movement and maintain control during cutting.

Conclusion

In this article, we have explored the key differences between fret saws and coping saws, highlighting their unique features, applications, advantages, and disadvantages. By understanding these distinctions, you can make an informed decision when selecting the right saw for your specific needs and project requirements.

Selecting the appropriate saw for the job is crucial for achieving successful project outcomes, whether you’re working on intricate woodworking tasks or general carpentry and home improvement projects. While fret saws offer superior precision for detailed work and tight curves, coping saws provide greater versatility and sturdiness for a wider range of materials and applications.

As you continue to hone your skills, we encourage you to experiment with both fret saws and coping saws to discover your personal preferences and expand your woodworking repertoire. By mastering the use of these essential tools, you’ll be better equipped to tackle any project with confidence and finesse.

Leave a Reply