Circular saws are versatile and powerful tools that can make quick work of various cutting tasks in woodworking, construction, and DIY projects. Although using a table with a circular saw can provide stability and precision, there are situations where working without a table is necessary or more convenient. In this comprehensive guide, we’ll explore how to use a circular saw without a table, ensuring you can tackle any cutting job with confidence and ease.

Using a circular saw freehand offers numerous benefits, including flexibility, portability, and the ability to work on larger or irregularly-shaped materials. By mastering the techniques for using a circular saw without a table, you can efficiently complete tasks in tight spaces or when a table is unavailable. Let’s dive into the essential tips and steps to help you make clean and accurate cuts while prioritizing safety and efficiency.

Safety Precautions: How to Use a Circular Saw Without a Table

Before diving into the process of using a circular saw without a table, it’s crucial to prioritize safety. Here are some essential safety precautions to keep in mind while operating a circular saw:

- Wear proper personal protective equipment (PPE): To minimize the risk of injury, always wear the appropriate PPE while using a circular saw. Essential protective gear includes:

- Safety goggles: To protect your eyes from flying debris and dust

- Ear protection: Earplugs or earmuffs to shield your ears from the loud noise generated by the saw

- Gloves: To protect your hands from potential cuts or splinters

- Dust mask: To prevent inhaling sawdust and other particles

- Inspect the saw for damage and proper functionality: Before using the circular saw, thoroughly inspect it to ensure it’s in good working condition. Check for any damaged or loose parts, ensure the blade is sharp and properly secured, and verify that the safety features, such as the blade guard, are functioning correctly.

- Ensure a clutter-free and well-lit workspace: A clean and organized workspace is vital for safe operation. Remove any debris, tools, or objects that could interfere with your work or cause tripping hazards. Additionally, make sure the area is well-lit to clearly see your cutting lines and avoid any potential hazards.

Choosing the Right Circular Saw

Selecting the right circular saw for your project is essential for achieving the best results. Here are some factors to consider when choosing a circular saw:

Types of circular saws

Circular saws come in various designs, each with its advantages and disadvantages. The two main categories are:

- Corded vs. cordless: Corded circular saws provide continuous power, making them suitable for extended periods of use. However, they require access to a power outlet and may limit mobility. Cordless circular saws, on the other hand, offer more freedom of movement, but their battery life may restrict the duration of use.

- Worm drive vs. sidewinder: Worm drive saws have the motor behind the blade, resulting in increased torque and cutting power. These saws are typically heavier and more expensive but excel in heavy-duty applications. Sidewinder saws have the motor positioned beside the blade, making them lighter and more compact, suitable for general cutting tasks and extended use.

Selecting the appropriate blade

Choosing the right blade for your project is crucial for clean and efficient cuts. Consider the following factors when selecting a blade:

- Blade size and type: Circular saw blades come in various sizes, typically ranging from 6 1/2 to 7 1/4 inches in diameter. Larger blades can cut through thicker materials, while smaller blades are easier to maneuver. The blade type should also match the material you’re cutting, such as wood, metal, or masonry.

- Tooth count and materials: The number of teeth on a blade affects the quality and speed of the cut. Blades with fewer teeth produce faster cuts but with rougher edges, while blades with more teeth create cleaner cuts but at a slower pace. Additionally, consider the tooth material, such as carbide-tipped or high-speed steel, to ensure durability and cutting performance.

When deciding on a circular saw, it’s also helpful to understand the differences between a circular saw and a reciprocating saw. Circular saws are excellent for making precise straight cuts, particularly in woodworking projects. In contrast, reciprocating saws are more suitable for demolition work, cutting in tight spaces, and making rough cuts in various materials. This comparison can help you determine which tool best suits your specific needs and projects.

Preparing the Material

Before making a cut with your circular saw, it’s essential to prepare the material properly. Follow these steps to ensure accurate and safe cuts:

- Measure and mark the cut line: Carefully measure the desired length or width of the cut and mark the cutting line using a pencil or chalk. For straight cuts, use a straight edge, such as a carpenter’s square or a level, to draw a precise line along the measured distance.

- Secure the material with clamps or a workbench: To prevent the material from shifting during the cutting process, secure it in place using clamps, a workbench, or sawhorses with built-in clamps. Ensure the material is stable and that the portion being cut off is adequately supported to minimize the risk of binding or kickback.

- Adjust the saw’s depth and bevel settings: Set the blade depth on your circular saw so that it extends approximately 1/4-inch below the material’s thickness. This setting minimizes the risk of accidental contact with the blade and reduces the chance of kickback. If you need to make a bevel cut, adjust the bevel angle on the saw accordingly. Always unplug or remove the battery from the saw before making any adjustments to the blade depth or bevel settings.

Making the Cut

Once you’ve prepared the material and set up the circular saw, it’s time to make the cut. Follow these steps to ensure a clean and accurate cut:

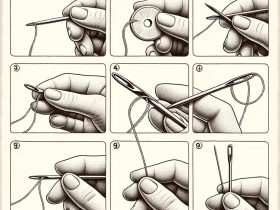

- Starting the saw and aligning the blade: Position the saw with the blade slightly away from the material’s edge. Turn on the saw and let it reach its full speed before gently lowering the blade onto the cut line. Align the blade with the marked line, using the saw’s built-in guide notch as a reference.

- Maintaining a steady cutting speed: As you cut, apply steady forward pressure to the saw, keeping the blade aligned with the cut line. Avoid forcing the saw through the material, which can cause the blade to bind or the motor to overheat. Instead, let the saw’s cutting speed dictate the pace.

- Using a straight edge or guide for precise cuts: For long, straight cuts, consider using a straight edge or cutting guide to ensure accuracy. Clamp a straight edge or guide parallel to the cut line, leaving enough space for the saw’s base to run smoothly along the edge. This setup will help maintain a straight cutting path.

- Handling plunge cuts and complex shapes: If you need to make a plunge cut or navigate complex shapes, start by making a small pilot hole or notch at the beginning of the cut. Carefully lower the saw’s blade into the pilot hole, keeping the saw’s base flat against the material. Proceed slowly and cautiously, maintaining control of the saw as you follow the marked cutting path. For intricate or curved cuts, consider using a jigsaw or a scroll saw instead.

Tips for Cleaner and Safer Cuts

Achieving clean and safe cuts with a circular saw requires careful attention to technique and best practices. Here are some tips to help you make cleaner and safer cuts:

- Using a high-quality blade: Investing in a high-quality blade designed for the specific material you’re cutting will result in cleaner, more efficient cuts. A sharp, durable blade minimizes the risk of chipping or tearing the material, ensuring a smooth finish.

- Letting the saw reach full speed before starting the cut: Before plunging the saw blade into the material, let it reach its full operating speed. Starting the cut at full speed ensures a clean entry point and reduces the risk of the blade snagging or binding.

- Allowing the saw to stop completely before lifting it from the material: After completing the cut, keep the saw in place and release the trigger, allowing the blade to come to a complete stop. Lifting the saw before the blade stops spinning can result in accidental damage to the material or injury.

- Preventing kickback and blade binding: Kickback occurs when the blade gets pinched or caught in the material, causing the saw to lurch back towards the user. To minimize the risk of kickback, ensure the material is adequately supported and clamped, maintain a firm grip on the saw, and use a riving knife or anti-kickback device if available. Additionally, avoid cutting with a dull or damaged blade and maintain a slow, steady cutting speed to prevent blade binding.

Conclusion

In this article, we have covered the essential steps and tips for using a circular saw without a table. By following these guidelines, you can achieve clean, accurate cuts while prioritizing safety. To recap, remember to:

- Take proper safety precautions, including wearing appropriate personal protective equipment.

- Choose the right circular saw and blade for your project, considering factors such as corded vs. cordless and worm drive vs. sidewinder saws.

- Prepare the material by measuring, marking, and securing it in place.

- Make the cut with proper technique, maintaining a steady cutting speed and using guides for straight cuts.

- Implement tips for cleaner and safer cuts, such as using a high-quality blade and preventing kickback and blade binding.

By practicing and mastering these techniques, you can confidently use a circular saw without a table for various woodworking projects. Take the time to familiarize yourself with your saw and always prioritize safety to ensure successful and enjoyable woodworking experiences.

FAQ

In this section, we’ve compiled a list of frequently asked questions related to using a circular saw without a table. These questions address common concerns and provide additional information that may not have been covered in the main article.

What is the best circular saw for beginners?

The best circular saw for beginners is one that is easy to use, has essential safety features, and offers good value for the money. Look for a saw with a comfortable grip, a reliable motor, and straightforward adjustments for depth and bevel settings. A sidewinder-style saw with a cord is often a good choice for beginners, as they are lighter, more affordable, and provide sufficient power for most DIY projects.

How do I choose the right circular saw blade for different materials?

To choose the right circular saw blade for different materials, consider factors like blade size, tooth count, and tooth material. For wood, a general-purpose blade with carbide-tipped teeth is versatile and suitable for most cuts. For cutting plywood or laminates, a blade with more teeth will produce cleaner cuts with less tear-out. For cutting metal or masonry, specialized blades with abrasive or diamond-tipped teeth are necessary.

How can I minimize tear-out when cutting plywood with a circular saw?

To minimize tear-out when cutting plywood with a circular saw, use a fine-toothed blade specifically designed for plywood or laminates. Additionally, place a strip of painter’s tape along the cut line before marking it, which helps reduce splintering. You can also use a straight edge or guide to ensure a precise cut, and cut with the good side facing down to further minimize tear-out on the visible side.

Can I use a circular saw to cut metal or plastic materials?

Yes, you can use a circular saw to cut metal or plastic materials, but you will need to use a specialized blade designed for the specific material you are cutting. For metal, choose a blade with abrasive or carbide-tipped teeth designed for cutting metal. For plastics, select a blade with a high tooth count and a configuration designed to prevent melting. Always follow safety precautions and guidelines when cutting any material with a circular saw.

What is the proper way to maintain and clean a circular saw?

The proper way to maintain and clean a circular saw involves regular inspection, cleaning, and lubrication. Before cleaning, always unplug the saw or remove the battery. Remove dust and debris from the saw using a brush or compressed air, paying special attention to the motor vents and the blade guard. Lubricate moving parts, such as the blade guard and height adjustment mechanism, with a dry lubricant. Periodically check for loose or damaged parts, and tighten or replace them as needed.

How do I know when it’s time to replace my circular saw blade?

It’s time to replace your circular saw blade when it becomes dull, damaged, or no longer produces clean cuts. Signs of a dull blade include increased difficulty in cutting, excessive chipping or tear-out, and burning on the cut edges. Inspect the blade for missing or damaged teeth, as this can also indicate the need for replacement. Regularly sharpening your blade can extend its life, but eventually, a new blade will be necessary for optimal performance.

Are there any alternative tools to a circular saw for making similar cuts?

Yes, there are alternative tools to a circular saw for making similar cuts, depending on the specific type of cut and material. For straight cuts in wood, a table saw or miter saw can provide clean, accurate cuts. A jigsaw is a versatile alternative for making curved or irregular cuts in wood, plastic, or thin metal. A reciprocating saw can be used for demolition work or cutting in tight spaces, while a track saw offers precise straight cuts with minimal setup time. Each tool has its own strengths and limitations, so choose the one that best suits your specific needs and project requirements.

References

- Lowe’s. (2020). Circular Saw. Retrieved April 6, 2023, from https://www.lowes.com/

- Johnson, C. (2018). The Family Handyman: Skills You Need – Using Circular Saws. Reader’s Digest Association. from https://www.familyhandyman.com/

- Woodworkers Journal. (2017). 10 Circular Saw Secrets: DIY Guy. Retrieved April 6, 2023, from https://www.woodworkersjournal.com/

Leave a Reply