Beeswax finishes have long been a popular choice for woodworkers and DIY enthusiasts seeking a natural, eco-friendly solution to protect and enhance the beauty of their wooden surfaces. With its rich history and traditional use, beeswax has earned a reputation as a go-to finish for various wood projects. However, before you decide to use beeswax on your wood, it’s essential to understand both the advantages and disadvantages of this timeless finish. In this article, we will delve into the drawbacks of beeswax finishes and explore the factors you should consider before applying it to your wood projects.

Advantages of Beeswax Wood Finish

Natural and eco-friendly

One of the primary benefits of using beeswax as a wood finish is its natural composition. Derived from bees, this wax is a renewable resource that has minimal environmental impact compared to synthetic finishes. Beeswax is also biodegradable and non-toxic, making it a safer option for both your home and the environment.

Enhances wood grain and appearance

Beeswax finish not only protects the wood but also brings out its natural beauty. When applied to wooden surfaces, beeswax enhances the grain patterns and deepens the color of the wood, giving it a warm and rich appearance. This feature makes it an ideal choice for antique furniture restoration and preserving the original charm of wooden pieces.

Easy to apply and maintain

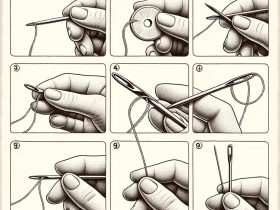

Another advantage of beeswax wood finish is its ease of application and maintenance. You can apply beeswax directly to the wood surface with a soft cloth or brush, and it requires no special tools or techniques. Furthermore, maintaining a beeswax finish is relatively simple; periodic reapplication and buffing will keep the wood looking fresh and well-protected.

Provides a protective barrier

Beeswax creates a protective barrier on the wood surface that helps shield it from moisture, dirt, and minor scratches. While it may not be as durable as some other finishes, beeswax still offers a level of protection that can prolong the life of your wooden items. This natural barrier also helps to prevent the wood from drying out and cracking over time, preserving its appearance and structural integrity.

Disadvantages of Beeswax Wood Finish

Limited durability and protection

- Susceptibility to water damage: While beeswax does offer some protection against moisture, it is not as resistant to water damage as other finishes like varnishes or polyurethane. Prolonged exposure to water or high humidity can cause the beeswax to break down, compromising its protective qualities and potentially leading to damage to the wood.

- Not resistant to heat or chemicals: Beeswax finishes are also sensitive to heat and chemicals. High temperatures can cause the wax to soften and become less effective, while exposure to harsh chemicals can degrade the finish and harm the wood underneath.

Requires regular reapplication

- How long does beeswax last: The lifespan of a beeswax fi nish depends on various factors, such as the environment and the amount of wear and tear the surface endures. Generally, beeswax finishes need reapplication every six to twelve months to maintain their protective qualities and appearance.

- The process of reapplying beeswax finish: Regular maintenance is necessary to keep a beeswax finish looking its best. This involves cleaning the surface, reapplying a fresh layer of wax, and buffing it to restore its luster. While this process is not difficult, it can be time-consuming, especially for larger pieces or multiple surfaces.

Longer drying time

Beeswax finishes tend to have a longer drying time compared to other finishes like oils or water-based options. Depending on the environment and the thickness of the applied layer, beeswax can take anywhere from a few hours to a couple of days to fully dry and harden. This extended drying time can be inconvenient and may delay the completion of your project.

Can attract dust and dirt

Due to its slightly tacky texture, beeswax can attract dust and dirt more readily than some other finishes. This may require more frequent cleaning to keep the wood surface looking clean and pristine. In addition, dust and dirt can become embedded in the wax over time, making it more challenging to maintain the finish’s original appearance.

Not suitable for all wood types and projects

While beeswax finishes work well on many types of wood, they may not be the best choice for every project. For instance, beeswax is not recommended for use on outdoor furniture, as it does not offer adequate protection against the elements. Additionally, some woodworkers may prefer a more durable finish for high-traffic areas or surfaces that come into contact with food or liquids. In these cases, alternative finishes like varnishes, shellacs, or polyurethane may be more appropriate.

Alternatives to Beeswax Wood Finish

Oil-based finishes

Oil-based finishes, such as tung oil, linseed oil, and Danish oil, are popular alternatives to beeswax for wood finishing. These finishes penetrate the wood surface, providing both protection and an attractive sheen. Oil-based finishes are generally more durable than beeswax and can offer better resistance to water and wear. However, they may require longer drying times and can darken the wood’s appearance over time.

Varnishes

Varnishes are another option for those seeking a more durable finish than beeswax. Made from resins dissolved in a solvent, varnishes create a hard, protective surface on the wood. They are available in various sheens, from matte to glossy, and provide excellent resistance to water, heat, and chemicals. Varnishes can be more challenging to apply than beeswax and may require more skill and experience to achieve a professional-looking result.

Shellac

Shellac is a natural resin secreted by the lac bug and dissolved in alcohol to create a versatile wood finish. It dries quickly, provides a beautiful shine, and is compatible with most other finishes. Shellac is less durable than varnishes but offers better protection than beeswax. It is often used as a sealant or primer under other finishes, and it can be easily repaired or removed if necessary.

Water-based finishes

Water-based finishes, such as water-based polyurethane or acrylics, are an eco-friendly alternative to beeswax and other solvent-based finishes. These finishes dry quickly, emit fewer volatile organic compounds (VOCs), and are easier to clean up. Water-based finishes provide a durable protective coating and are available in various sheens. However, they may raise the wood grain during application and require more coats to achieve the desired level of protection and appearance.

How to Choose the Right Wood Finish

Assessing your project needs

Before selecting a wood finish, it’s essential to consider the specific requirements of your project. Think about the intended use of the finished piece, the level of protection needed, and the environment in which it will be placed. For example, outdoor furniture or surfaces in high-traffic areas may require a more durable and water-resistant finish, while decorative items or heirloom pieces might call for a finish that enhances the wood’s natural beauty.

Considering the wood type

The type of wood you are working with can also influence your choice of finish. Certain finishes may be better suited for specific wood species, while others may not be compatible or may alter the wood’s appearance in undesirable ways. Research the best finishes for your particular wood type and consider consulting with experienced woodworkers or professional finishers for guidance.

Balancing aesthetics and functionality

When choosing a wood finish, it’s essential to strike a balance between aesthetics and functionality. While a particular finish may look stunning, it may not offer the level of protection or durability you require for your project. Conversely, a highly durable finish might not provide the desired appearance or feel. Consider your priorities and select a finish that meets both your aesthetic and functional needs.

Evaluating maintenance requirements

Finally, consider the maintenance requirements of the various wood finishes. Some finishes, like beeswax, require more frequent reapplication and upkeep, while others, such as varnishes or water-based finishes, may be more durable and low-maintenance. Think about how much time and effort you are willing to invest in maintaining the finish and choose one that aligns with your expectations and lifestyle.

Conclusion

In this article, we’ve explored the disadvantages of beeswax wood finish, including its limited durability and protection, the need for regular reapplication, longer drying time, its tendency to attract dust and dirt, and its unsuitability for certain wood types and projects. It is important to weigh the pros and cons of beeswax finish before deciding whether it is the right choice for your specific needs.

When selecting a wood finish, consider not only the advantages and disadvantages of beeswax but also the alternative options, such as oil-based finishes, varnishes, shellac, and water-based finishes. By carefully evaluating your project requirements, wood type, desired aesthetics, and maintenance expectations, you can choose the best finish to achieve the results you’re looking for. Don’t be afraid to explore different finishes and consult with experienced woodworkers or professional finishers to make the most informed decision for your woodworking projects.

FAQ

In addition to the information provided in the article, we’ve compiled a list of frequently asked questions to address any further concerns or inquiries you may have about beeswax finishes and alternative options. These questions aim to cover topics that were not explicitly discussed in the article to provide a more comprehensive understanding of wood finishes.

Can I use beeswax finish on painted or stained wood?

Yes, you can use beeswax finish on painted or stained wood. Beeswax can enhance the appearance and provide a protective layer to the surface. However, it’s essential to ensure that the paint or stain is fully dry before applying the beeswax finish. Additionally, the beeswax may alter the final appearance or sheen of the painted or stained surface, so it’s a good idea to test the finish on a small inconspicuous area before applying it to the entire piece.

How can I remove beeswax finish from wood surfaces?

To remove beeswax finish from wood surfaces, you can use a combination of heat and a gentle solvent. Use a hairdryer or heat gun on a low setting to warm the wax, making it easier to remove. Then, use a clean, lint-free cloth dampened with mineral spirits or a similar gentle solvent to wipe away the softened wax. Be sure to work in a well-ventilated area and follow the safety instructions on the solvent label. Once the beeswax is removed, you may need to lightly sand the surface to prepare it for a new finish.

Is beeswax finish safe for use on cutting boards or other food contact surfaces?

Beeswax finish is generally considered safe for use on cutting boards and other food contact surfaces, as it is a natural, non-toxic material. However, it’s essential to use pure, unadulterated beeswax and avoid any products containing added chemicals or synthetic ingredients. Some beeswax finishes may also be mixed with food-grade oils, such as mineral oil, to create a more durable and protective finish for food contact surfaces.

How can I achieve a higher gloss with a beeswax finish?

To achieve a higher gloss with a beeswax finish, you can buff the surface after the application of the beeswax. First, ensure that the beeswax has been applied evenly and has had enough time to dry, typically at least 24 hours. Then, use a clean, lint-free cloth or a soft buffing pad to vigorously rub the surface in a circular motion. The friction generated by the buffing process will create heat, which helps to further melt the wax into the wood and produce a higher gloss. You can also add a second or third layer of beeswax, allowing each layer to dry and buffing between applications for an even glossier finish.

Can I mix beeswax with other finishes to improve its properties?

Yes, you can mix beeswax with other finishes to enhance its properties or create a custom finish that suits your specific needs. Common combinations include mixing beeswax with oils, such as linseed oil, tung oil, or mineral oil, to improve durability, water resistance, and ease of application. Another popular option is combining beeswax with other waxes, like carnauba or paraffin, to create a harder or more water-resistant finish. Always test your custom mix on a small, inconspicuous area before applying it to the entire piece to ensure it produces the desired result.

What are the differences between beeswax finish and other wax finishes, like carnauba or paraffin wax?

Beeswax, carnauba, and paraffin wax are all different types of waxes used for wood finishing. Beeswax is a natural wax derived from honeybees, and it has a soft, pliable texture with a pleasant aroma. It provides a warm glow and enhances wood grain but offers limited durability and protection. Carnauba wax, derived from the leaves of the carnauba palm, is a harder wax with a higher melting point, making it more durable and water-resistant than beeswax. Paraffin wax is a petroleum-based wax that is more affordable and widely available but may lack the eco-friendliness and natural appeal of beeswax and carnauba wax. Each type of wax has its own advantages and disadvantages, and the choice depends on factors such as desired appearance, durability, and environmental considerations.

How does humidity or temperature affect the application and performance of beeswax finish?

Humidity and temperature can impact the application and performance of beeswax finish. High humidity levels can slow down the drying process and make it more challenging to achieve a smooth, even finish. It is recommended to apply beeswax finish in a climate-controlled environment or during periods of lower humidity to ensure proper drying and adhesion. Temperature also plays a role in the application and performance of beeswax finish. Cold temperatures can cause the wax to harden and become more challenging to work with, while excessive heat may cause the wax to become too soft or even melt. Ideally, apply beeswax finish in a well-ventilated area with a stable temperature between 60-80°F (15-27°C) for optimal results.

Are there any precautions or safety measures to consider when using beeswax finish?

When using beeswax finish, it is essential to follow some basic safety measures and precautions. Ensure that your workspace is well-ventilated, as the application process can produce fumes from solvents or oils mixed with the beeswax. Avoid working near open flames or heat sources, as beeswax and some solvents are flammable. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect your skin and eyes from potential irritation. If you are working with beeswax mixed with solvents or other chemicals, carefully read and follow the manufacturer’s safety instructions and recommendations.

Can I apply beeswax finish over an existing finish, or does the wood surface need to be stripped first?

It is possible to apply beeswax finish over an existing finish, but the success depends on the compatibility of the two finishes and the condition of the existing finish. In general, beeswax finish adheres well to oil-based finishes, but it may not adhere properly to other finishes like varnish, shellac, or water-based finishes. Before applying beeswax over an existing finish, clean the surface thoroughly to remove any dirt, dust, or grease, and lightly sand the surface to create a better bond. It’s always a good idea to test the compatibility of the finishes on a small, inconspicuous area before proceeding with the entire piece.

How can I best store leftover beeswax finish for future use?

To store leftover beeswax finish, transfer it to an airtight container, such as a glass jar or a plastic container with a tight-fitting lid. Store the container in a cool, dry place away from direct sunlight, heat sources, and moisture. Beeswax has a long shelf life and can be stored for an extended period if properly sealed and stored in a suitable environment. When you need to use the stored beeswax finish, check its consistency and appearance to ensure it has not degraded or become contaminated before applying it to your project.

References

- Fenton, P. (2019). Wood Finishing Basics. Taunton Press.

- Hoadley, R. B. (2010). Understanding Wood: A Craftsman’s Guide to Wood Technology. Taunton Press.

- Maloof, S. (2001). Sam Maloof: Woodworker. Kodansha International.

Leave a Reply